On Wednesday, Adrian was down in London, in the rather grand Somerset House. Only he was in the basement, a former Government department mail room, which the RSA had turned into a festival of making for the day called RSA Future Maker.

They held it there, rather than in their very nice building a few minutes walk away, because they're helping to turn it into a makerspace, and that seemed the perfect location for their kick-off event to get to know the maker community in the UK.

It was an interesting day, and in addition to showing off some Internet of Things devices, Adrian also spoke about the challenges of moving from being a maker (of one Read on for his slides and notes from the talk...

Thanks for inviting me to speak here today.

I'm Adrian McEwen. I think I've been a maker all my life, but I've only been doing it as my work for the past five or so years.

Most of what I, and my company MCQN Ltd, make are connected devices, what's called the Internet of Things.

It's the next wave in the Internet's development: first we connected computers to each other; then to mobile phones; now we're going to connect everything else.

So most of my talk today will be filtered through that perspective on the world. It's a bit of a grab bag of ideas, theories and problems that I've hit while moving from building individual items to building lots of something.

Hopefully it will spark some wider discussion about the issues, and maybe we can work towards some solutions.

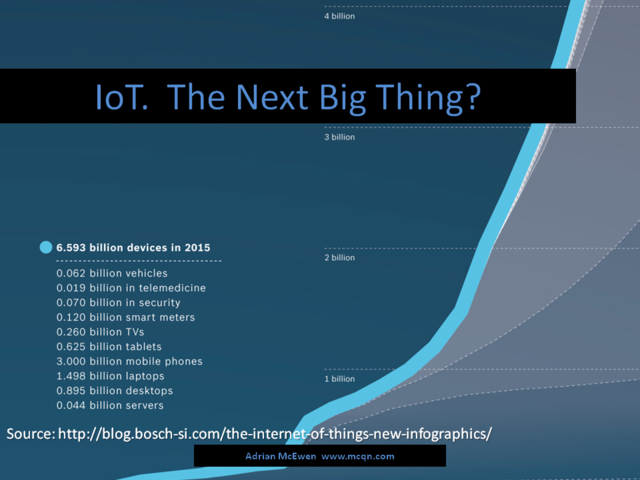

Don't worry, this is the only slide with a boring graph on it ;-)

Why should you care about the trials of some maker of connected devices? Well, one reason is that the Internet of Things is going to be huge. It's where the web was in the mid-90s - lots of people playing around with it, everyone can see it's going to change how the world works, but no-one knows exactly how.

Like mobile phones, Europe and the UK in particular are at the forefront of this. Let's try not to emulate the trajectory of mobile where it shines brightly then crashes and burns just as mobile properly takes off.

The traditional approach would be to pour funding into universities and company R&D departments. They then hand the new inventions to the production and sales departments of the companies, who go off and commercialise the technology.

I'm not saying that approach can't work, there's every chance that the interesting ideas in the Internet of Things will come out of an R&D team. However, there's an equal chance that it will come from...

...someone's shed...

...or dining room table...

...in their garage...

...at their local makerspace or hackspace...

...or in their bedroom instead of doing their homework.

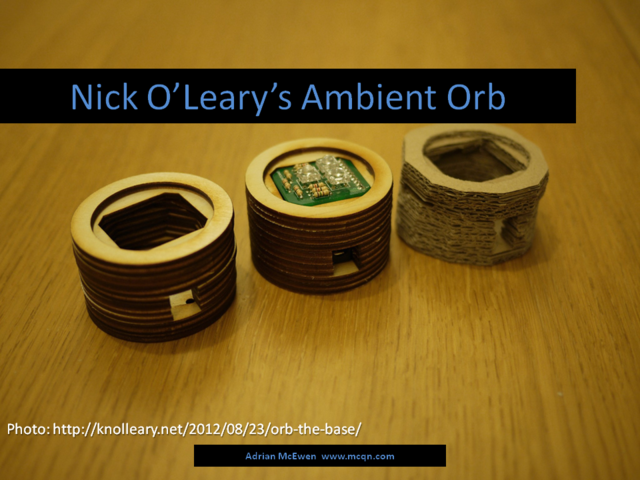

People experimenting with things in the own time, like Nick O'Leary's ambient orb

Or scratching their own itch, like Russell Davies' [Boris] Bikemap.

And I could have picked any number of examples from the pages of Make Magazine or from the Hack-a-Day website.

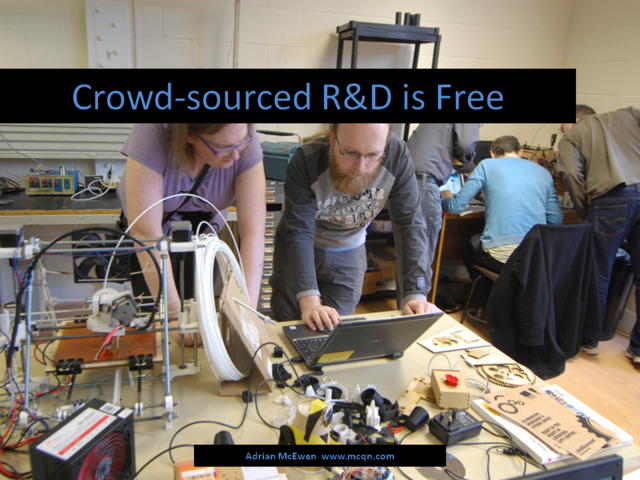

The Maker Movement, and the low cost of prototyping tools, have taken R&D out of the lab and made it a massively distributed network of invention.

The problem then, isn't "how do we find the applications for the Internet of Things", but rather how to help makers turn their ideas into products.

How do we help the individual maker who has built a cool device to solve a problem that she had, only to discover that her friends and people online want one?

There's some sort of market there for it, but is it enough to build a business around? And even if it is, how do you go about that?

One of the ways we're trying to help with that is at DoES Liverpool, which I co-founded. It's the home for tech startups and makers in Liverpool.

It's part makerspace - we've got a laser-cutter, 3D printers, oscilloscopes, etc. - but also a co-working space, so we get web developers, app coders, and so on, but also a translator, charity worker, and other business people working there.

It's a community which will hopefully act as a melting pot to generate new ideas and send people off in new directions. Plus it has a real breadth of skills available for the members to tap into, on a more informal level than going and asking for explicit business support.

The events and mailing list extend the community out into the wider city, and cover both technical topics and the business side of building a startup.

And I'm sharing some of what I've learned by writing a book to introduce people to the process.

Part of what makes the Internet of Things so interesting is that it cuts across so many disciplines: software, electronics, product design, business...

Designing the Internet of Things gives an overview of all these areas - prototyping with Arduino or Raspberry Pi, and laser-cutting and 3D printing, then how you scale that up to making PCBs and injection-moulding. Plus chapters looking at design principles, business models and the ethical considerations of the new technology.

It's being published by Wiley in the autumn, and you can pre-order it on Amazon now.

The people at the coal-face are doing a great job in talking to each other and sharing experience and ideas. Things like #IoTLondon, which is over-subscribed each month, and maker faires, hackdays and the rest, mean there's lots of peer-support around.

Even today, I know most of the other people presenting, and have usually met them a few times in the past at assorted events.

But more people taking things to the next stage would be good.

So, what haven't we started to address?

Costs is one. There's a gulf in cost between making a couple of something, and making thousands of something. There's a matching, and welcome, drop in the cost of making each individual item, but the up-front costs of tooling, etc. are a huge barrier when you don't have an established company to back you up.

I have that problem with Bubblino - at present they're repurposed off-the-shelf bubble machines, built in small batches. Scaling up manufacture could bring the price of each unit down significantly, which would probably give a bigger market, but there's a massive step between the up-front costs for each approach.

And tooling up isn't the only big cost involved, there's also certification...

Even if you use the newer digital fabrication techniques to allow a middle ground of scale of manufacture, because the Internet of Things involves electronics as well as just bits of wood and metal, there's the problem of certification.

Want to sell in the EU? Your distributors will want your product to be CE marked. Have a radio module in it for, say, WiFi? Then you'll need to check its emissions - that's for the CE mark in Europe, and FCC certification in the US. If you're selling to the US then there's also U/L, a different certification system, and other countries around the world have their own schemes.

Obviously these regulations are there for a reason, but getting through them could cost you anything from £3k-20k. You can't spread that sort of cost across 100 units.

With car manufacture, there's the concept of Single Type Approval. If you build a kit-car, a qualified engineer will give it the once-over and give you an okay. Could we design something similar for electronics? Or what if the TSB funded certification rather than R&D? Or maybe there's opportunity for a company doing testing where they batch products together or provide more rigorous self-testing first, or something...

And if you're happy taking on the risk of meeting all these costs, raising the money is easier said than done, as we've found with Good Night Lamp. This is an Internet of Things startup with a family of connected Lamps, and I'm the CTO.

Kickstarter is one funding option, and we had a reasonable amount of success with that - great for raising our profile and finding potential distributors - but the demographic of Kickstarter users is better for more obvious "gadgets" or dev boards and it's hard if you don't fall into that market segment. We had an ambitious target (see my earlier comments about costs...) and so didn't meet it.

We'd also been talking to venture capitalists, angel investors, etc. before our Kickstarter campaign, and since, and that's also a really hard sell. The investment scene in the UK seems more cautious than in the US, but both sets are much happier backing apps or web startups, and are playing a waiting game when it comes to hardware.

[For some more background on this, check out http://designswarm.com/blog/2013/03/internet-of-things-a-european-advantage/ or http://designswarm.com/blog/2013/05/map-of-internet-of-things-companies-in-the-uk-europe/ from Good Night Lamp founder Alexandra Deschamps-Sonsino. She's been feeling the funding pain more than I have, as I get to focus more on the (more fun) hard technical problems]

Finally, how do we sell these new connected devices? Where does it live in John Lewis for example? At the moment all the "tech stuff" gets corralled into the hifi and AV sections, but that doesn't work for the Internet of Things. Does Good Night Lamp live in the lighting department, or next to the printers? Is Voy's Ugle owl an ornament or a phone "accessory"?

We're picking at that problem too, with an initiative called Category Free Retail. Ping @CFRetail on twitter if you want to get involved.

Thank you. Any questions?