It's been a while since our last update; generally because there was a bit too much going on and then too much to report. Doh. We're going to take a leaf out of fellow indie manufacturer Electric Flapjack's book and split the catch-up posts across project, rather than temporal, lines. The client projects we had on have continued, so there's been a regular drum-beat of air quality sensor and Bluetooth and e-paper work; we're not going to delve any further into those, and rather focus on the product side of MCQN.

The biggest news items relate to Museum in a Box.

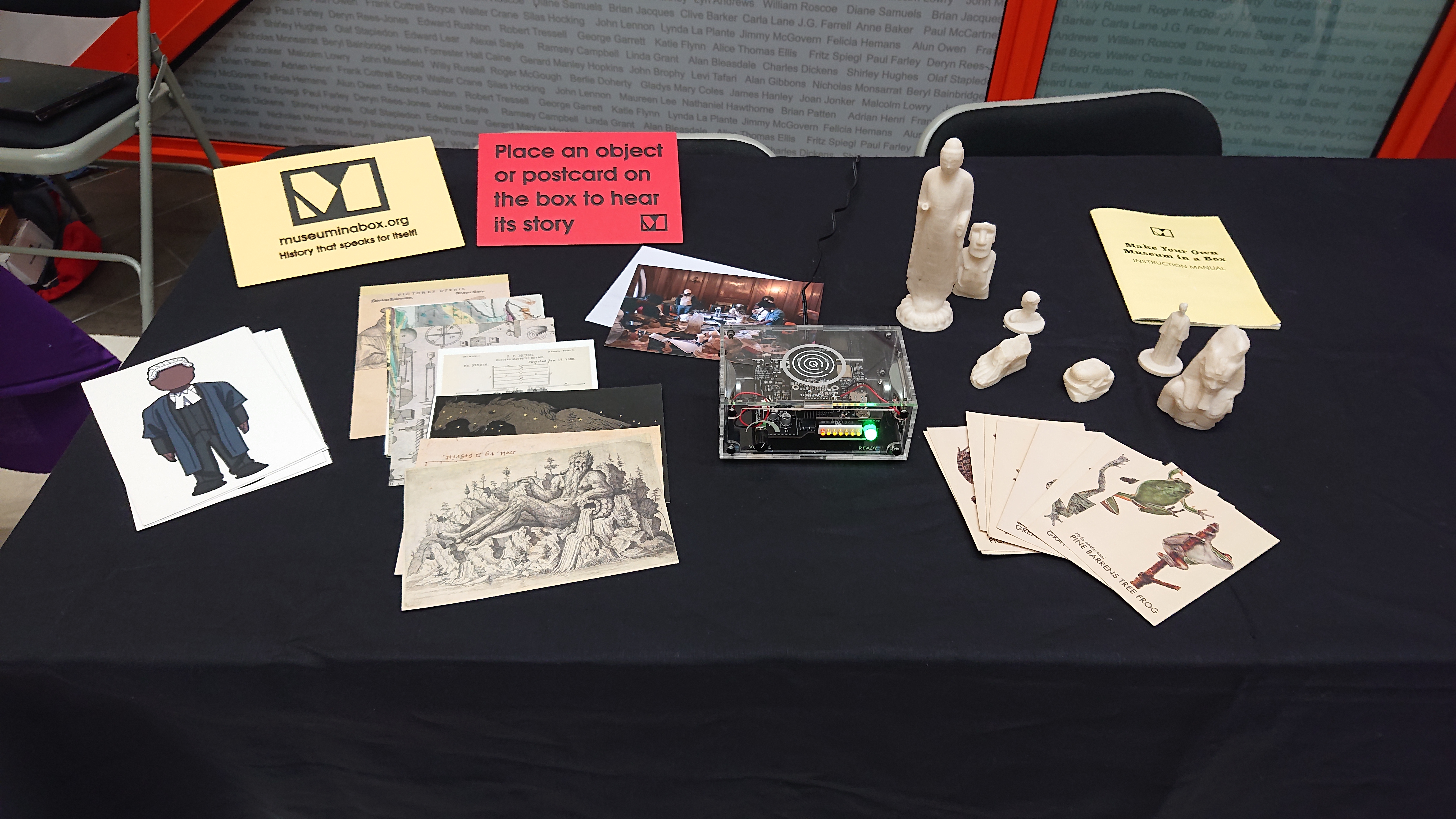

Back in 2015 a collaboration with George Oates and Tom Flynn grew into a company making boxes that played back audio when they encountered objects or postcards that had been enchanted with NFC tags. We were involved from the outset, but somewhat behind the scenes, designing the electronics and writing the software powering the Box.

The company had been steadily growing and ramping up production until the pandemic hit. And more importantly, the knock-on effect of the global chip shortage that followed.

In December 2020 we made our second production batch and wondered if we might have survived the shock of the pandemic. In the second half of 2021 we scrambled to pull together all the parts we needed for the third batch as the chip shortage bit. Thankfully close relationships with our suppliers (thanks Pimoroni!) tipped us off about the impending shortage early in planning for the batch, so we could secure enough of the Raspberry Pi single-board computers that powered the Box; tracking down the last few electronic components for the custom PCB was a challenge—we ended up paying £10 each for the real-time clock chips, which had been 80p in earlier batches!

Batch 3 went into production in December 2021 with over half the batch already pre-sold. The rest sold fairly quicly and then we were stuck. Like the rest of the world, we couldn't get hold of any more Raspberry Pis and it wasn't clear when things would get any better.

Museum in a Box is dead; long live Museum in a Box!

So for most of 2022 Museum in a Box was in limbo.

The lack of Raspberry Pi boards and some quality issues with the RFID readers we were using were pointing towards some pretty major re-engineering work.

Plus there were some major developments in the non-technical side of the business. George, who had been running things until then, agreed to lead the new Flickr Foundation; which meant leaving Museum in a Box.

As a result, in summer 2023 we wound up Museum in a Box the company, with MCQN Ltd taking over support of the cloud platform and existing boxes out in the world.

Then we could get on with the redesign to get the Boxes back into production. The eagle-eyed among you might spot that the timing of that coincides with us getting too busy to be updating things here...

New electronics; who dis?

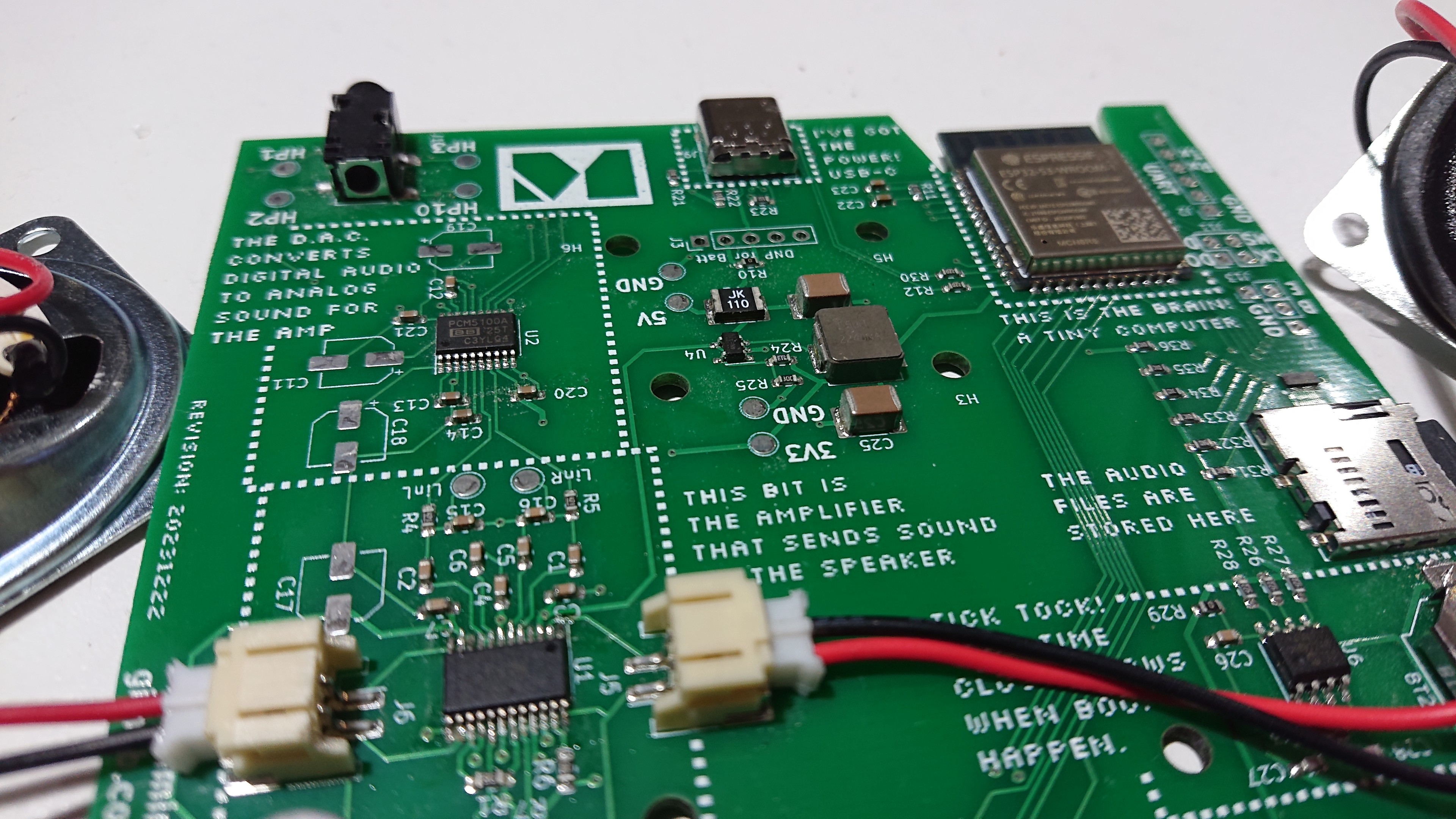

Given our expertise, the ESP32 microcontroller modules were an obvious candidate for replacing the Raspberry Pi. They're less capable than the Pi, but perfectly capable of the needs of Museum in a Box. They also bring a bunch of advantages: software updates will be easier to manage; and the start up time is much faster. We also chose the ESP32-S3 version, which has USB capabilities; our hope is that it will let us use USB as an alternative to WiFi for getting content onto the device.

Chris got stuck into the electronics, adding the parts that we'd lose from removing the Raspberry Pi: the processor and WiFi module itself, but also the regulator to generate the 3.3V powering most of the circuitry and the micro-SD card to hold the vital audio files.

We wrapped up 2023 by sending the finished main board PCB files over to the manufacturing plant.

The change in computing module had a knock-on effect of requiring a complete re-write of the software running on the Box. We'd started work on that with some off-the-shelf development boards while the PCB design work was ongoing, and it continued alongside the hardware manufacturing steps.

Although our main electronics manufacturing happens up in Glasgow, they (understandably) were closed over the Christmas period. To get a few boards made for the software development and to double-check the hardware design we took advantage of China not celebrating New Year at the start of January and ordered from there. We started our New Year with some shiny new hardware!

Vicino: opening up New Field Capabilities

As mentioned, we'd been having quality issues with the RFID boards from the old design. In the ones we'd bought for Batch 3 we had an 84% failure rate!!! Our suspicion was that they were nearing end of life and that was the result of the bottom of assorted warehousing barrels being scraped.

We'd been on the hunt for a replacement for a while, but as more of a background process. That level of duds plus our need to rewrite all the software anyway meant it was time to find a replacement.

After looking at off-the-shelf PCN532-based boards and getting mixed results, we investigated rolling our own. Although Museum in a Box only needs an RFID reader, we decided to limit our investigations to those which also supported NFC; we have some ongoing research interests in that area, and it makes sense to build expertise and a codebase that suits both bases.

Our initial choice was the TRF7970A, but we found it extremely hard to coax the sample library and dev board into life. We eventually admitted defeat and tried the ST25R3916. That proved much more receptive to our efforts. We'd found our chip.

Antenna design is a little out of our comfort zone with circuit layout, so we pulled in the expertise of Factoree for the hardware while we focused on the software library to talk to it.

Before we went to production we needed to fine-tune the antenna. We got a couple of bare PCBs fabbed and it fell to Chris to populate the components for reflowing. That included hand placing three of the insanely small varicaps on each board. They measure 0.6mm by 0.6mm, have four pads, and need to be placed in the correct orientation. You can just about make one out in the photo above.

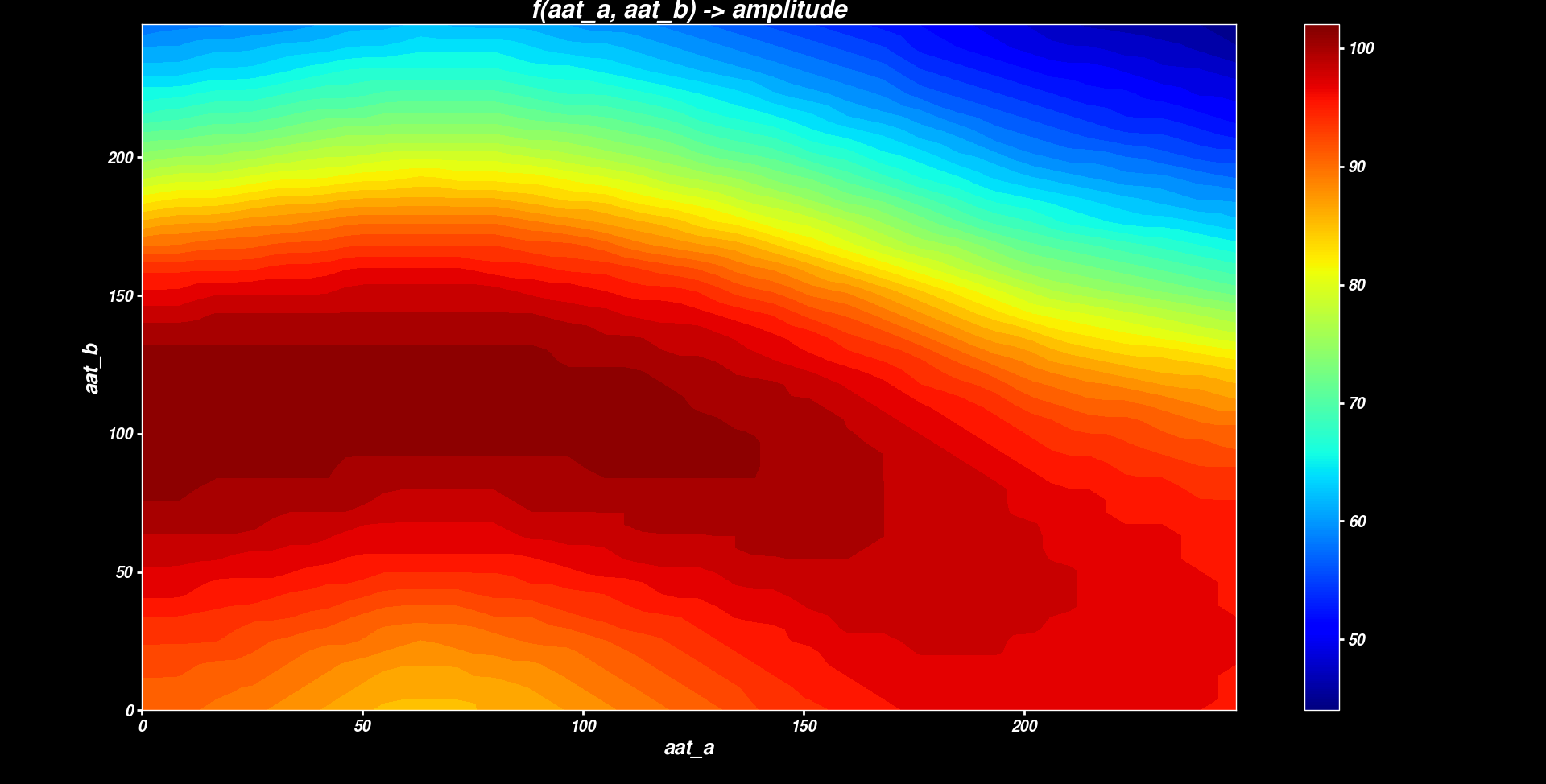

With a board successfully soldered up, Adrian set about testing. The varicaps have 256 levels of variation, and the chip can report the strength of the resulting NFC field. We wrote some test code to step through the full range of variation in both sets of varicaps, printing it out over serial, and then did some post-processing to create heat maps like the one above. That let us experiment with swapping out various of the fixed capacitors in the circuit to narrow in on the best values to use to get the most performance range with the varicaps.

After all that was done, we could get a production run of boards (with the varicaps placed by robot!) to let us finish manufacturing Batch 4.

We deliberately got more boards than we needed for Museum in a Box. That's so that we have some to use for our other explorations; and to let us add them to the MCQN store on Tindie for anyone else who's after an RFID/NFC board. The design is open and we've also had it certified by OSHWA as UK000061.

Boxes loved by the British Library

It was tight, but we managed to get the software functionally-complete and ready to use, and all the Boxes built, in time for our deadline. In March we shipped 66 Boxes down to the British Library.

They, in turn, shipped pairs of them out to all of their partner libraries across the country; ready for use in the satellite exhibitions of Beyond the Bassline, a celebration of 500 years of black British music.

We've published a full write-up of that as a case study over on the Museum in a Box website.

Batch 5 On Sale Now!

With the Boxes back in production we could let the many, very patient, folk on the waitlist know that they were available. That took up the rest of Batch 4, so over the summer we kicked off production of Batch 5.

And that brings us up to date for Museum in a Box. The redesign is done and batch 5 is ready and available to buy in the shop.