Chris this week, and a week behind but in my defence last week my blood was 75% Menthol, Honey and Lemon and my nose was 100%, well you don’t need to know.

We have been busy shipping Museums in Boxes, so much so that a new batch has been ordered and you can expect some box assembling in upcoming weeknotes. We’ve got boxes heading to Bath, Massachusetts and Oregon as I type. We’re still Antarctica short of a box on every continent so anyone with a contact at the BAS who wants Penguins in a Box is welcome to get in touch.

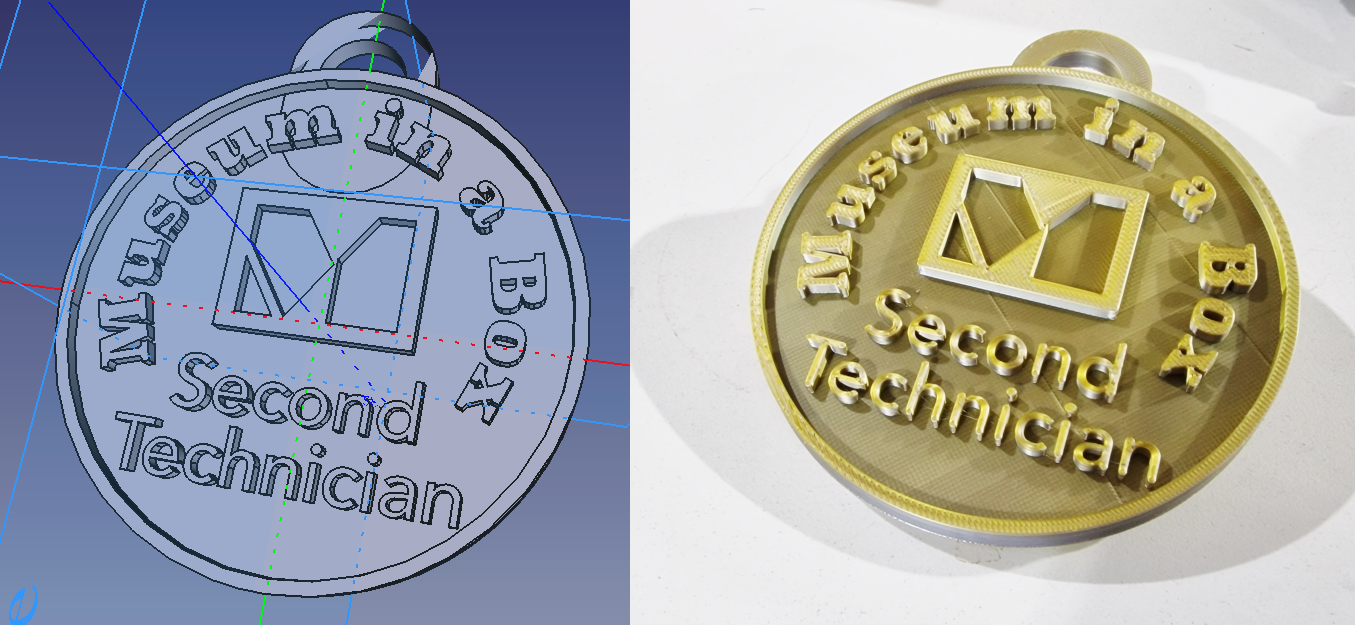

I got to join in with Freecad Friday with a quick badge design. A Museum in a Box in Reading developed a fault and after doing our best to fix it remotely we decided it needed to come back to us for some open front surgery. (Swapping out a potentially faulty SD card.) After discussion with the customer they decided they would like to have a go at the fix themselves. Assembling and disassembling boxes is routine for us, and we have instructions on our website to show people how, but if you’ve never done it before it can be a daunting task. So to celebrate their intrepid spirit we conferred the title ‘Second technician’. Of course a title isn’t worth much unless there is a badge to go with it, and we have a 3d printer or two so we made them one.

With a new batch of Museum in a Box boxes due it’s also the time we’re working through inventories and collecting together all the components that make up a box. Most of the laser cutting is done off site but as part of the pcb assembly there is a small acrylic shim that needs to be consigned for pcb fabrication. These have been cut and posted so they’re ready for the soldering of the display lights board. We’re not a completely JIT manufacturer but with some getting lost in transit we might have got close with this component.

Adrian finished the My Bike’s Got LED packaging he talked about in the last weeknotes. With a tweak to the tabs that hold the board in place, and extending the battery panel to hook in place it’s good to ship. With the nights drawing in and a finite number of days left until Christmas you could do worse than look at our Tindie store

Adrian has also moved the Hexanoodle project on, adding the CH32V203F8 chip to the Arduino platform for CH32, as a first step to being able to program the Hexanoodle boards from Arduino.