Fortnight-notes this time, with Adrian back at the keyboard and in vim.

I don’t think we ever got round to a grand announcement when Neil came in to help us look at some of the marketing, website, etc. for both MCQN and Museum in a Box (given they have relatively separate Internet presences). He just snuck in and started working on things. He’s had a similarly French exit—leaving us with a “What would Neil do?” (ask for photos, generally) catchphrase; a stack of things still to work through; and a better understanding of our marketing priorities.

I’m not sure referencing geek command-line editors in the opening sentence of the weeknotes is quite what he had in mind, but still.

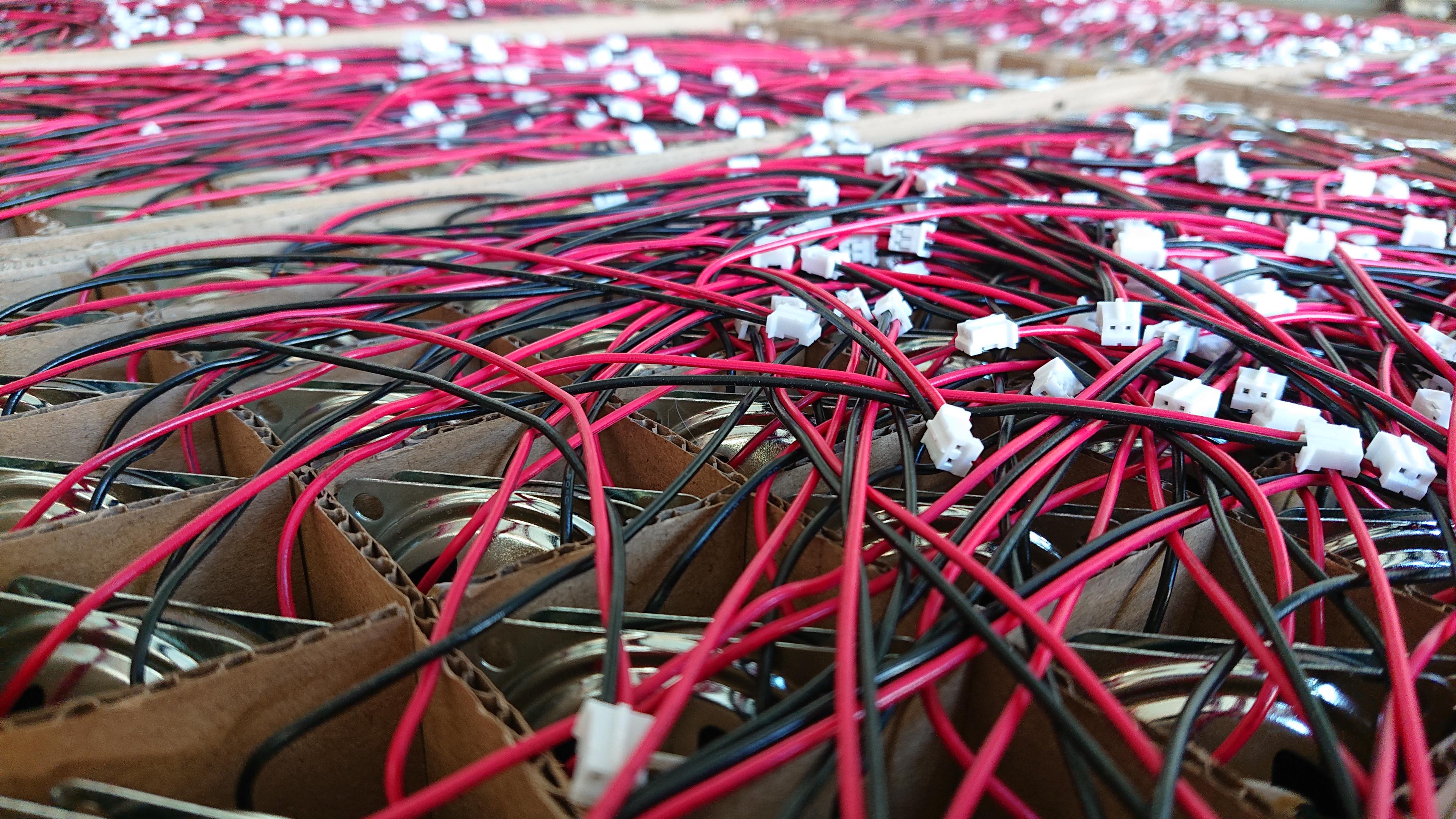

Production of future batches of Museum in a Box took a good step forwards this week as we took delivery of a thousand speakers. We (and by we, I mean I) need to get the rest of the manufacturing steps kicked off too, so we’ve got something to plug them into. Especially as we’ve been sending out more Boxes to happy customers; further dwindling the remaining stock in Batch 5.

I also got the write-up of my talk at Rise and Design: Design in the Heritage Sector finished and published on the Museum in a Box blog.

Continuing our celebration of Open Hardware Month, Chris submitted the updated My Bike’s Got LED and related Lightbeam projects to the OSHWA for accreditation.

Alongside this he is updating the documentation for these projects, including what’s possibly our first zine-style user manual; and with dark nights drawing in our minds are focused on all things LED, so he also worked on running repairs for some of the Joyride My Bike’s got LED devices.

My focus for My Bike’s Got LED has been on the packaging. I think the board is great, and the kit has all the parts you’d need to pimp out your bike; however, I’ve had a reticence to be shouting about it. Some of that is my natural aversion to blowing our own trumpet, but I worked out that some of it is that what we were shipping out didn’t match the quality of the product.

So the zine that Chris has been working on is part of that; and the other is to take a leaf out of Museum in a Box’s book and design a custom insert for the packaging. I had some initial thoughts on how that would work; spent lots of time trawling through packaging supplier websites looking for something suitable and off-the-shelf for the outer box; and then did some prototyping with the component parts while getting an order ready to ship. The prototyping resulted in me finding a better way to pull it all together, and we ended up deciding that the Museum in a Box box is near enough to the right size (it’s a bit bigger than we need, but not by much) that the benefit of just keeping one shipping box in stock for both products means we’ll go with that. Next step will be to design and prototype the insert.

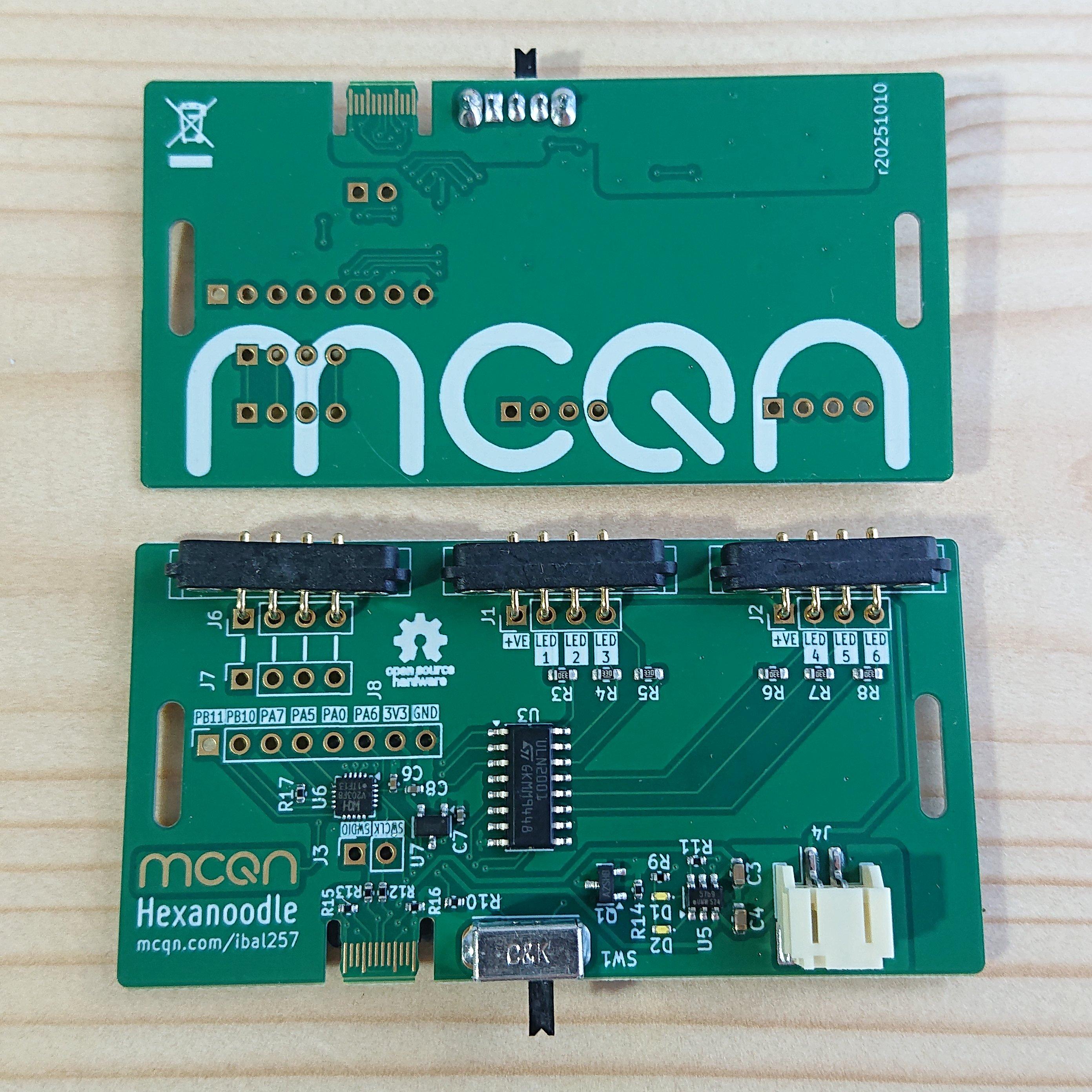

I made a mistake in the design for the new Hexanoodle that we mentioned in the last weeknotes. It turns out that as well as the number of pins (20), the package type (QFN), and the chip size (3x3mm), there’s also a choice of two lead pitches (the spacing of the pins round the edge of the chip): 0.4mm and 0.45mm. I’d managed to pick the wrong one in the initial version that I shipped off to manufacturing.

Thankfully it got caught in the initial manufacturing checks and so the only cost was time. I had to cancel that order and resubmit a fixed version.

In the interim I’d also heard that the abusing-WS2812-chips design I was running with might not work as I’d hoped. It seems that it might still be okay but re-thinking it made me realise that I didn’t need the WS2812 chips at all. That was an initial design direction from when it was going to be a micro:bit add-on; as I’d since decided to add a CH32-family processor onto it, there were actually enough pins available to drive the LEDs directly. That meant I could drop three chips from the design which, given the crazy low prices of items from LCSC, didn’t make a huge difference to the bill-of-materials cost but all helps. I might also be able to trim a little from the size with fewer chips to find room for, but I went with fewer changes for a faster re-design for these initial prototypes.

That slowed down me getting the physical PCBs to try out, but they landed on my desk on Friday.

The initial checks were good. The no-connector USB-C has a tiny bit of wiggle to it, but provides power just fine—hopefully it’ll do data too once I get to bringing up the processor—and the charging circuit and 3.3V regulators all pass basic tests.

Now I need to get to grips with coding for the CH32 processors and get some code onto it to see if that side of things works.