At Maker Assembly Manchester I took part in the session about making and manufacturing.

Each of the panellists gave a talk and then we followed it with a discussion between the panellists and the audience, chaired by James Tooze. The slides and notes from my talk are below.

Hello, I'm Adrian McEwen. I'm a maker...

...and also a co-founder of DoES Liverpool - the makerspace and community in Liverpool.

With makerspaces we've got a pretty good handle now on making one of almost anything, but what happens when you want to move beyond that?

For example, and picking something that I've been going through this exact process with, say you've built an Internet-connected bell. This is a photo of the prototype, which was cut on the DoES Liverpool laser-cutter and has stripboard and breakout-board circuitry inside.

Generally, the next step is DfM. Design for Manufacture. But what does that mean?

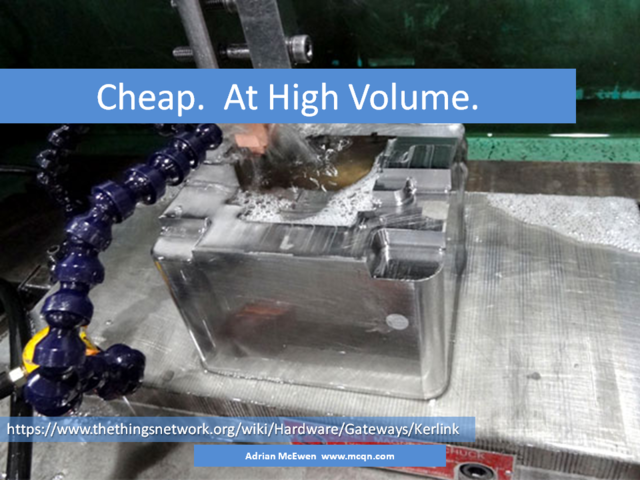

Usually it means "Design for Mass-Manufacture". It optimises for lowest unit-cost, but only achieves that by cranking up the volume made. Set-up costs for tooling in injection-moulding, etc. run into thousands of pounds, so it only makes sense if you're making 10s of 1000s of units to spread the cost across.

To jump from one to those sorts of volumes is a pretty big gamble and needs lots of capital.

DfSM: Design for Scaling Manufacture?

Are there intermediate steps we can take to scale production more gradually? That would let maker businesses grow organically, and find the right place on the supply and demand curve for their product - better-using resources and making many more (not-really) niche products viable.

It also gives us more variety in materials. Wood...

...or ceramics.

What else could we use?

And how do we find out what the options are?

How do you learn about these processes or how to access them?

Your local makerspace or hackspace. They're not perfect, but the communities that grow around makerspaces - with the maker culture of openness and sharing - are the best place (the only place?) that you can find that sort of thing out.

As more members of DoES Liverpool build projects which outgrow the capabilities of the workshop we slowly grow our network of contacts, and knowledge, of how to scale our manufacturing and just as importantly, where you can get access to those facilities.

It's something I've been looking at specifically of late, as part of the Future Makespaces in Redistributed Manufacturing project that [the session's chair] James is running.

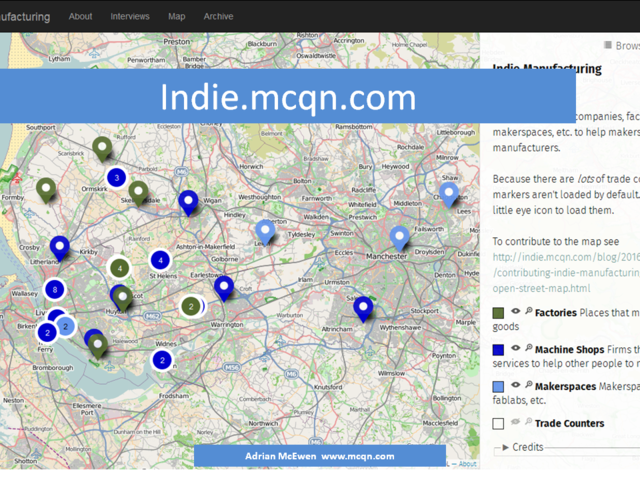

We've spent time touring industrial estates...

...and talking to the community and trying to capture that data in Open Street Map and sharing it on our Indie Manufacturing website - indie.mcqn.com.

However, the map is a poor substitute for the folk knowledge available through the community.

We need more people making things. More people scaling up to manufacturing. And more people sharing what they've done and how they do it.

![Df[a panoply of]M](https://mcqn.com/files/images/MakerAssembly-DfM/Slide01.png)